Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 30, 2024 Visit:113 Source:Roll Forming Machine Factory

The roll forming machine process is a crucial aspect in the manufacturing industry, particularly for the production of various metal components and structures. Enhancing the efficiency of this process can lead to significant improvements in productivity, cost savings, and overall product quality. Here, we explore several strategies to enhance the efficiency of roll forming machine processes.

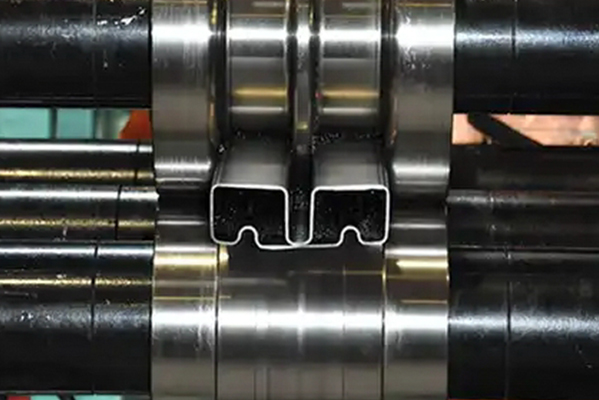

1. Optimization of Roll Tooling Design

The design of roll tooling plays a pivotal role in the efficiency of the roll forming process. By optimizing the tooling design, manufacturers can minimize material waste, reduce the number of passes required, and enhance the overall precision of the formed parts. This can be achieved through advanced computer-aided design (CAD) and simulation software, which allow for precise modeling and testing of roll tooling configurations before physical production.

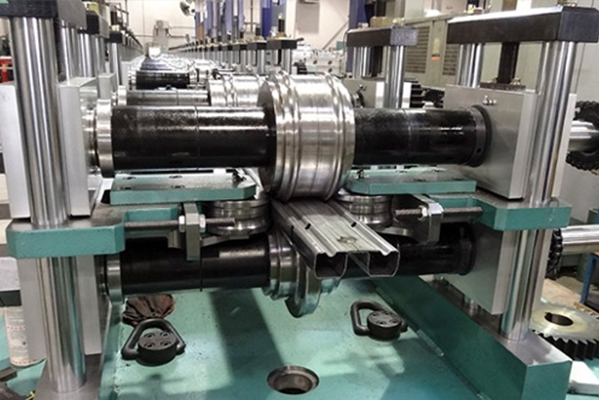

2. Advanced Automation and Control Systems

Incorporating advanced automation and control systems can greatly enhance the efficiency of roll forming machines. Automated feeders, sensors, and robotic arms can streamline the material handling process, reducing the need for manual intervention. Additionally, advanced control systems can optimize machine settings in real-time, ensuring consistent and accurate forming of parts. These systems can also provide valuable feedback for further process improvements.

3. Continuous Monitoring and Maintenance

Regular monitoring and maintenance of roll forming machines are essential for maintaining high levels of efficiency. By conducting routine inspections, manufacturers can identify and address potential issues before they lead to more significant problems. Preventive maintenance, such as regular lubrication, wear part replacement, and alignment checks, can help extend the lifespan of the equipment and ensure optimal performance.

4. Process Analysis and Improvement Techniques

Implementing process analysis and improvement techniques, such as Six Sigma or Lean Manufacturing, can help identify inefficiencies and waste within the roll forming process. These methodologies involve detailed analysis of the current process, identifying root causes of variation and waste, and developing targeted improvement measures. By continuously refining the process, manufacturers can achieve significant gains in efficiency and productivity.

5. Operator Training and Development

The skills and knowledge of the operators play a crucial role in the efficiency of roll forming machine processes. Providing comprehensive training and ongoing development opportunities can help ensure that operators are equipped with the necessary skills to operate the machines effectively. This includes training on new technologies, best practices, and safety protocols. Well-trained operators are more likely to identify and address potential issues, leading to smoother and more efficient production processes.

6. Material Handling and Storage Improvements

Optimizing material handling and storage practices can also enhance the efficiency of roll forming machine processes. By improving the layout of the production area, reducing material handling distances, and implementing efficient storage solutions, manufacturers can minimize downtime and streamline the production workflow. Additionally, using material handling equipment such as conveyors and lift tables can further enhance the efficiency of the process.

Conclusion

Enhancing the efficiency of roll forming machine processes requires a multifaceted approach that includes optimization of roll tooling design, incorporation of advanced automation and control systems, continuous monitoring and maintenance, process analysis and improvement techniques, operator training and development, and material handling and storage improvements. By implementing these strategies, manufacturers can achieve significant gains in productivity, cost savings, and overall product quality. The key is to remain adaptable and continuously seek out opportunities for improvement, ensuring that the roll forming process remains efficient and competitive in the evolving manufacturing landscape.