Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Feb 20, 2025 Visit:43 Source:Roll Forming Machine Factory

A roll forming machine is a specialized piece of equipment used in various manufacturing industries. It plays a crucial role in the continuous formation of metal sheets or strips into specific cross - sectional shapes.

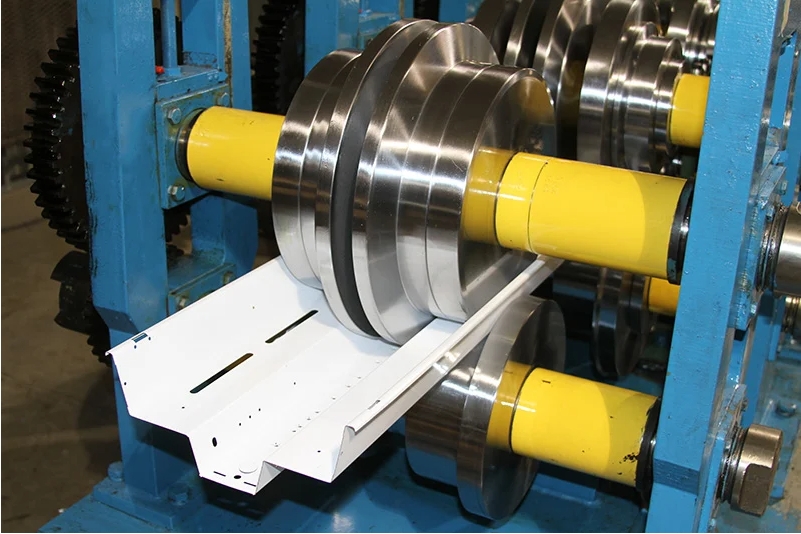

The working principle of a roll forming machine is based on a series of rollers. These rollers are arranged in a specific pattern and are precision - machined to gradually bend and shape the incoming metal material. As the metal sheet or strip passes through the machine, it encounters a series of sets of rollers. Each set of rollers applies a certain amount of force, gradually changing the shape of the metal until it reaches the desired profile.

There are many applications for roll forming machines. In the construction industry, for example, they are used to form components such as roof panels, side boards for cars (as mentioned in some references), and other structural elements. The machine can produce these components with relatively high speed and precision. For instance, a car side board roll forming machine can customize the roll forming speed according to different requirements, and different cutters will be equipped accordingly. Hydraulic devices are often used to control parts like uncoilers and cutters, while PLC (Programmable Logic Controller) controls the entire production line using famous brand modules and parts, ensuring the good precision of the finished products.

Roll forming machines can handle a variety of materials. Commonly, materials like steel (including low - carbon steel sheets such as Q235 mentioned in the first reference), color steel sheets (as seen in the second reference) are used. These materials have different thicknesses and yield strengths, and the roll forming machine can be adjusted accordingly to accommodate the specific properties of the material. For example, the thickness of raw material for a metal tile forming machine (related to roll forming) can range from 0.3 - 0.8mm with a yield strength of 235MPa.

In terms of production capacity, different roll forming machines have different capabilities. Some machines can produce a relatively large quantity per month, like 10 units per month as stated in the first reference, while others may be able to handle larger volumes depending on their design and the nature of the products being manufactured. And some roll forming machines are fully automatic, such as the 750 - type roof panel roll forming machine which has characteristics like light weight, high strength, heavy bearing capacity and good earthquake resistance, and it is widely used in multi - high - rise steel structure buildings.

In conclusion, a roll forming machine is an essential tool in modern manufacturing, especially in the metal - working sector, enabling efficient and precise production of a wide range of metal components with different shapes and specifications.