Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Nov 04, 2024 Visit:148 Source:Roll Forming Machine Factory

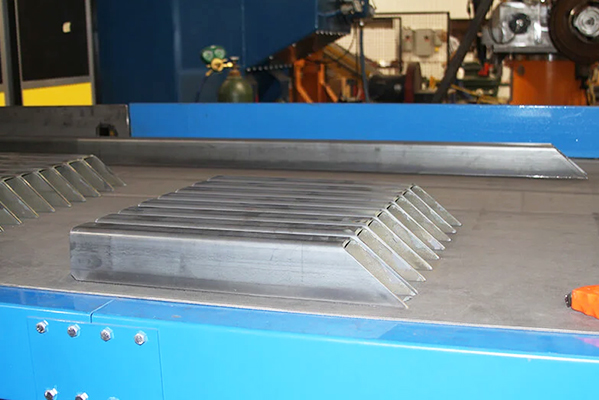

The pricing of roll forming machines is a complex interplay of various market dynamics and trends that shape the landscape for both manufacturers and consumers. Roll forming machines, which are used to shape metal sheets into desired profiles through a series of rolling dies, are crucial in industries such as construction, automotive, and aerospace. This article explores the key factors influencing the pricing of these machines.

Supply and Demand Dynamics

One of the fundamental drivers of roll forming machine pricing is the balance between supply and demand. When demand for these machines exceeds supply, manufacturers may increase prices due to the scarcity of available units. Conversely, if supply outweighs demand, prices may decrease as manufacturers compete for market share by offering discounts or promotions.

Demand for roll forming machines can be influenced by economic growth, technological advancements, and shifts in consumer preferences. For instance, an increase in demand for lightweight, high-strength materials in the automotive industry can drive up the demand for roll forming machines capable of producing such materials.

Technological Innovations

Technological advancements play a significant role in determining the pricing of roll forming machines. As manufacturers invest in research and development to create more efficient and advanced machines, the cost of production often rises. These increased costs are typically reflected in the pricing of newer models.

However, technological innovations can also lead to cost efficiencies in the long run. Advanced automation and precision engineering can reduce labor costs and increase production volumes, which can help offset the initial higher costs and stabilize pricing.

Market Competition

The level of competition within the roll forming machine market also affects pricing. In highly competitive markets, manufacturers may engage in price wars to gain market share, leading to lower prices. Conversely, in markets with limited competition, manufacturers may have more pricing power and be able to charge higher prices for their products.

The degree of competition can vary by region and by the type of roll forming machine. For example, the market for high-precision, automated roll forming machines may be less competitive due to the specialized nature of the product, allowing manufacturers to charge premium prices.

Economic Conditions

Economic conditions play a crucial role in shaping roll forming machine pricing. During periods of economic growth, businesses tend to invest more in capital equipment, including roll forming machines, which can lead to increased demand and higher prices. Conversely, during economic downturns, businesses may cut back on investments, leading to a decrease in demand and lower prices.

Currency fluctuations and trade policies can also impact pricing. For instance, a strengthening domestic currency may make imported roll forming machines more affordable, while tariffs and trade restrictions can increase the cost of imported machines.

Customization and Specialization

The trend towards customization and specialization in roll forming machines is also influencing pricing. As manufacturers increasingly offer tailored solutions to meet specific customer needs, the cost of production can rise due to the complexity and uniqueness of each project. This can lead to higher pricing for customized machines compared to standard models.

However, customization can also create value for customers by providing solutions that are better suited to their specific applications, which may justify the higher cost. Manufacturers that offer customization services may be able to differentiate themselves from competitors and command higher prices for their unique offerings.

Conclusion

In conclusion, the pricing of roll forming machines is influenced by a multitude of market dynamics and trends, including supply and demand, technological advancements, market competition, economic conditions, and customization and specialization. Understanding these factors is essential for both manufacturers and consumers to make informed decisions and navigate the competitive roll forming machine market effectively. As the industry continues to evolve, staying abreast of these dynamics will be crucial for success in this dynamic sector.