Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Mar 04, 2025 Visit:2 Source:Roll Forming Machine Factory

A forming tool is a specialized device used in manufacturing and fabrication to shape materials into specific geometries without removing any material. This process, known as forming, is essential for creating components with precise dimensions and complex shapes. From metalworking to plastics and composites, forming tools are integral to a wide range of industries. This article explores the applications, types, and benefits of forming tools, emphasizing their role in modern production processes.

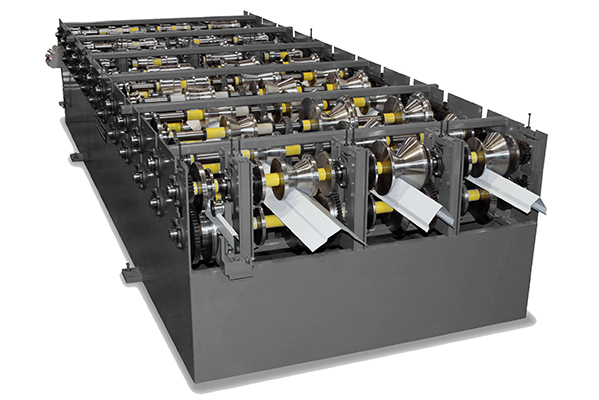

In metalworking, forming tools are widely used to manipulate sheet metal, rods, and other raw materials into desired shapes. For instance, press brakes and stamping dies are common forming tools that bend and cut metal sheets to create parts for automotive bodies, appliances, and machinery. These tools ensure high precision and repeatability, making them indispensable in mass production. Similarly, rolling mills use forming tools to flatten or shape metal into sheets, plates, or structural profiles.

The plastics industry also relies heavily on forming tools for processes like injection molding and thermoforming. Injection molding tools shape molten plastic into intricate components, such as electronic housings or medical devices, while thermoforming tools heat plastic sheets and mold them into products like packaging trays or automotive interiors. These applications highlight the versatility of forming tools in producing lightweight and durable items.

In the aerospace and construction sectors, forming tools are critical for working with composite materials. Tools used in composite forming enable the creation of strong, lightweight parts like aircraft wings or wind turbine blades. By applying heat and pressure, these tools ensure that materials like carbon fiber and fiberglass are shaped to meet stringent performance requirements.

The benefits of using forming tools include reduced material waste, improved efficiency, and the ability to produce complex designs with tight tolerances. These tools also minimize the need for additional machining or finishing, saving time and costs in the production process.

In conclusion, a forming tool is a vital component of modern manufacturing, enabling the efficient and precise shaping of materials for countless applications. Whether used in metal, plastics, or composites, forming tools continue to drive innovation and enhance production capabilities across industries. As technology advances, the importance of forming tools will only grow, solidifying their role in the future of manufacturing.