Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Mar 04, 2025 Visit:2 Source:Roll Forming Machine Factory

The molding machine is a cornerstone of modern manufacturing, designed to shape raw materials into precise and complex forms. Its primary purpose is to produce components and products by injecting, compressing, or casting materials such as plastic, metal, or rubber into molds. This article delves into the functions, types, and significance of molding machines across various industries.

One of the most common applications of a molding machine is in the production of plastic products. Injection molding machines, for example, melt plastic pellets and inject the molten material into molds to create items like containers, automotive parts, and household goods. Similarly, blow molding machines are used to manufacture hollow objects such as bottles and tanks. These processes ensure high precision, repeatability, and efficiency, making molding machines indispensable in mass production.

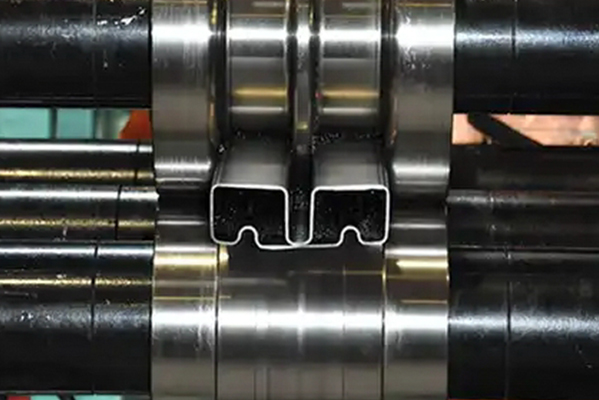

In the metalworking industry, molding machines are utilized for die casting and forging. Die casting machines inject molten metal into molds to produce intricate components with excellent surface finishes, often used in electronics, automotive, and aerospace sectors. Forging machines, on the other hand, shape metal by applying compressive force, resulting in strong and durable parts like gears and crankshafts.

Rubber and composite materials also benefit from molding machines. Compression molding machines, for instance, are used to create rubber seals, gaskets, and composite parts by applying heat and pressure to raw materials within a mold. This process ensures consistent quality and durability, meeting the demands of industries such as construction, healthcare, and electronics.

The advantages of using a molding machine include high production speed, minimal material waste, and the ability to create complex geometries with tight tolerances. These machines also reduce labor costs and enhance product consistency, making them vital for achieving competitive manufacturing standards.

In conclusion, the molding machine serves a critical role in transforming raw materials into functional and intricate products. Its versatility and efficiency have made it a key player in industries ranging from plastics and metals to rubber and composites. As technology continues to evolve, molding machines will undoubtedly remain at the forefront of innovation, driving progress in manufacturing and production processes worldwide.