Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Feb 20, 2025 Visit:27 Source:Roll Forming Machine Factory

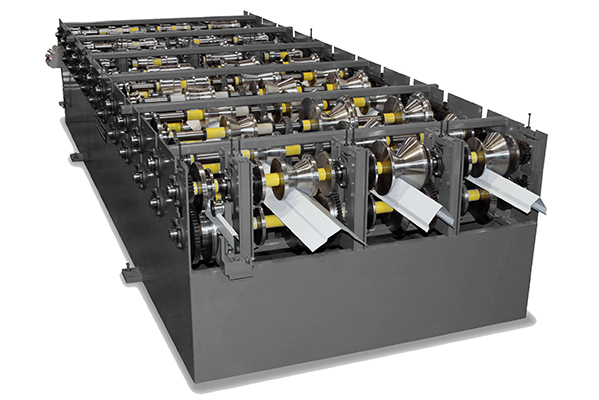

the roll forming machine is a remarkable piece of equipment. Among the various aspects that define its performance, speed is a crucial factor. Understanding what the speed of a roll forming machine is can help in evaluating its efficiency and suitability for different production requirements.

The speed of a roll forming machine is determined by multiple factors. Firstly, the design of the machine itself plays a significant role. Advanced machinery with optimized roller configurations and more efficient drive systems can generally achieve higher speeds. For example, some high-end roll forming machines are equipped with precision-engineered rollers and high-performance motors, enabling them to operate at relatively fast speeds while maintaining high precision.

The nature of the material being processed also affects the speed. Softer and more ductile materials may allow for higher forming speeds, as they require less force and energy to be shaped. On the other hand, harder and thicker materials may necessitate slower speeds to ensure proper forming and avoid issues such as deformation or damage.

Production requirements further influence the speed. In mass production scenarios where a large number of components are needed, higher speeds are often desirable. However, this must be balanced with the quality standards required. If the production involves complex or highly precise parts, the speed may need to be adjusted appropriately to guarantee consistent quality.

The speed of a roll forming machine can typically range from a few meters per minute to several tens of meters per minute, depending on the specific design, material, and production requirements. For instance, in the production of simple and common metal profiles, the speed might be on the higher end of this range, while for more intricate or specialized parts, the speed may be lower.

In conclusion, the speed of a roll forming machine is a complex interplay of various factors. It is influenced by the machine's design, the material being processed, and the production requirements. By carefully considering these elements, manufacturers can optimize the speed of their roll forming machines to achieve an ideal balance between efficiency and quality, thereby maximizing their production potential.