Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Feb 25, 2025 Visit:5 Source:Roll Forming Machine Factory

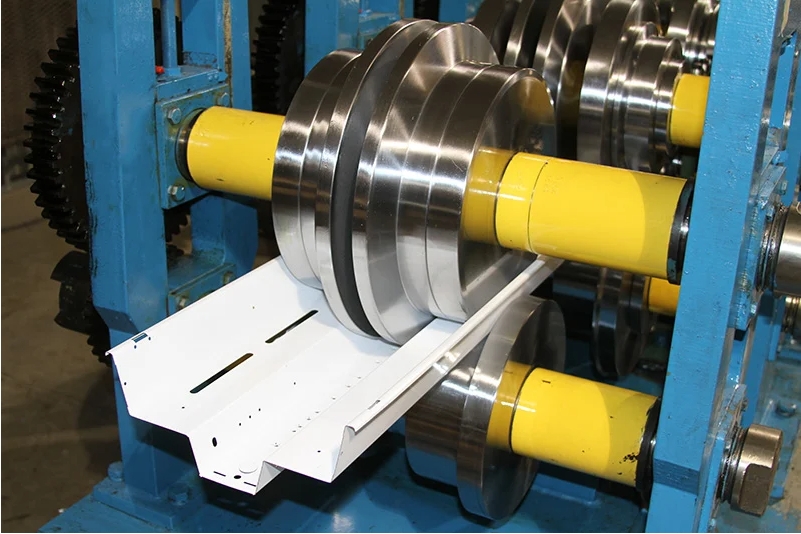

Main Applications of Slip Roll Forming Machines

Slip roll forming machines are widely used in industries that require curved or cylindrical metal parts. Some of its most common applications include:

1. HVAC systems: Slip roll forming machines are used to produce ducts and ventilation components, which often require a precise cylindrical shape for efficient airflow.

2. Construction: In the construction industry, the machine is used to create curved roof panels, gutters, and downspouts, which are critical for both functionality and aesthetics.

3. Automotive manufacturing: Slip roll forming machines can form metal parts such as exhaust pipes, roll cages, and curved body panels, ensuring durability and precision.

4. Industrial equipment: Many types of machinery and equipment require curved metal parts, such as conveyor belts, water tanks, and housings, which can be efficiently produced using slip roll forming machines.

5. Art and design: In addition to industrial applications, slip roll forming machines are also used in art and architectural projects to create custom metal sculptures, decorative elements, and unique structural designs.

Advantages of Using a Slip Roll Forming Machine

The slip roll forming machine offers several advantages that make it a top choice for producing curved metal parts:

1. Precision and consistency: Adjustable rollers allow for precise control of the metal’s curvature and diameter, ensuring consistent results.

2. Versatility: The machine can handle a wide range of materials, including steel, aluminum, and copper, as well as a variety of thicknesses and widths.

3. Efficiency: The continuous bending process reduces production time and labor costs, making it ideal for high-volume production.

4. Customization: Slip roll forming machines can be customized to produce unique shapes and sizes, meeting the specific needs of different projects.

Conclusion

The slip roll forming machine is a highly specialized and versatile tool that plays a key role in modern metal fabrication. Its ability to produce precise, curved, and cylindrical parts makes it an integral part of industries such as HVAC, construction, automotive manufacturing, and even art and design. As a roll forming machine, it embodies the innovation and efficiency that defines contemporary manufacturing processes. Whether for functional or aesthetic purposes, the slip roll forming machine is constantly shaping the world around us, one curve at a time.